How the building of 2 different toy planes can take on many paths and problems

BY APRIL MITCHELL

At Inventors Digest, our cover and Inventor Spotlight stories often take you behind the scenes to show how an invention or product evolved. This includes how it was conceived, and the often arduous journey to retail space.

Let’s take a nosedive into the making of two toy airplane products that recently hit the retail space. Both took time and lots of experimentation to get just right. Both are unique, and both share similar triumphs and challenges—with totally different flight paths to completion.

Whether inventing, manufacturing, selling your product yourself or inventing and licensing your invention to another company, it will need to go through many steps and/or iterations.

Both products here have a unique story. What will yours be?

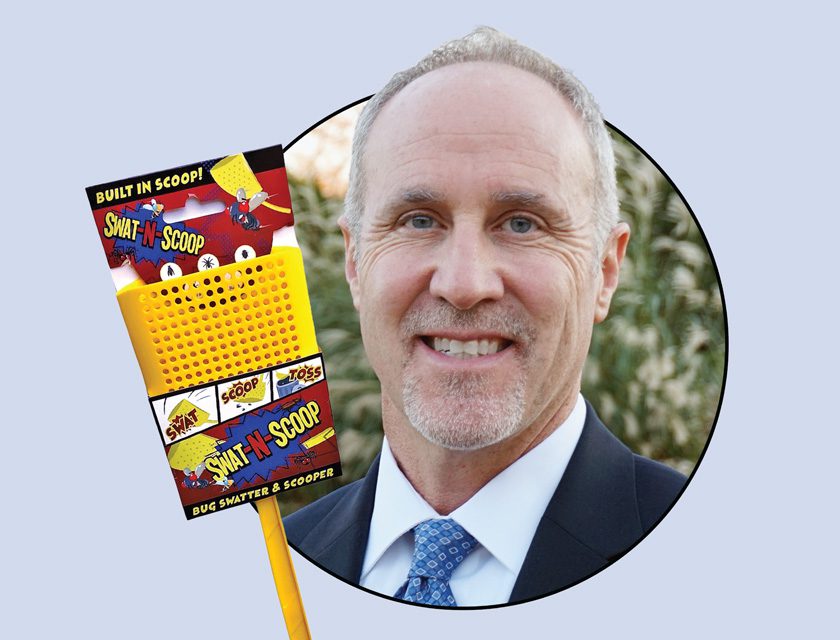

Sky High Flyer, by NSG

nsgproducts.com/products/nsg-sky-high-flyer?variant=42932790132906

How it flies: Grab the plane by the top and load it onto a traditional flying disc by spinning it onto a bolt located on the top middle of the disc, throw it into the air either underhand or Frisbee style, and watch as the plane separates from the disc and soar on its own.

There is some flexibility with how you play with the Sky High Flyer, depending on your skill level.

The plane screws onto the disc fully in four or five revolutions. If you have experience throwing a flying disc, it is recommended you tighten it fully before launching the disc. If you are a young child or inexperienced at throwing a flying disc, screw the plane down with only two or three revolutions so it will release from the disc sooner once thrown.

An idea takes wing: Sky High Flyer is the creation of independent inventor Terry Alan of Source Concepts LLC. He brought his invention to the attention of Eugene Cluney at NSG Products to review in hopes of licensing it. They set up a Zoom meeting where Alan showed Cluney his initial concept and prototype—and Cluney was instantly hooked on the idea.

The toy took some time going from prototype to retail ready. It was a game at one time and had a few different versions before Alan pitched it to Cluney.

Alan had built an initial prototype using a balsa plane that he shared with Cluney. It functioned well, but they were concerned about the longevity of the product and how it would hold up after multiple uses.

They decided it would be best to find a more durable material that would still function as intended.

“We didn’t realize it at the time, but this would prove to be quite a challenge: finding the right material that was strong enough to hold up over time yet lightweight to properly function,” Cluney said.

In time, they found a high-density, flexible foam material that fit the bill.

They also had the issue of attaching the plane to the disk. The nut-and-bolt system were heavy in comparison to the weight of the plane.

It took multiple rounds of sampling and testing for them to find the exact spot on the plane to insert the bolt for peak performance. They moved the location of the bolt on the plane closer to the front or further to the back to test the samples. These adjustments, by

as little as a centimeter, would completely alter the flight.

“We easily went through 15 to 20 samples before finalizing the item,” Cluney said. “After changing the plane from the inventor’s balsa wood to a more durable foam plane, finding the perfect release

from the disc and flight of the plane was much more difficult than we had originally intended.”

This process was mostly trial and error for the NSG team. Experiments included making planes with different material and density, testing their flights off the disc, and trying different locations for the bolt until they found the perfect combination.

NSG Products has a manufacturing patent on the Sky High Flyer that helps protect it from knock-offs. There are molds for all components of the product. All of the assembly is done by the factory before shipping it out.

“Luckily, this is a fairly simple product that does not require extensive assembly,” Cluney said. “It is really just making sure the nut-and-bolt system is secured to the disc and the assembled plane.”

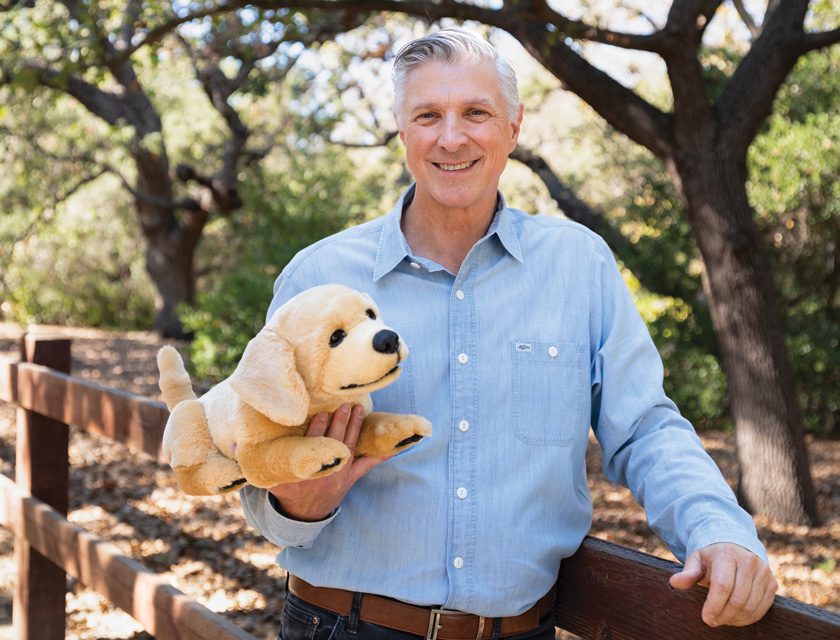

Aero-Storm Pneumatic Airplane, by Top Secret Toys

topsecrettoys.us/products/aero-storm-toy-airplane

How it flies: This motorized plane with real motor sounds requires no

batteries, using a revolutionary, patented micro air pressure-powered engine. Place the pump over the nose of the plane on a flat surface, give 20 or 25 full-length pumps, hold the plane underneath with wings parallel to the ground, flick the propeller and throw—and watch it perform corkscrews, loops, bank turns and more.

With its micro air engine, the Aero-Storm can also self-start if tossed into the wind by someone older who can throw it harder than a child.

An idea takes wing: The story behind this toy plane is full of twists and turns, as one concept evolved into another and sparked innovation.

Just as with the Sky High Flyer, “There were many difficulties involved in producing a durable product anyone could fly,” said Steve Rehkemper, co-inventor of the Aero-Storm.

He and brother/co-inventor Jeff Rehkemper are also the owners of Top Secret Toys, which manufactures and sells the product. The brothers worked on the Air Hogs airplane years before the Aero-Storm Pneumatic Airplane was invented.

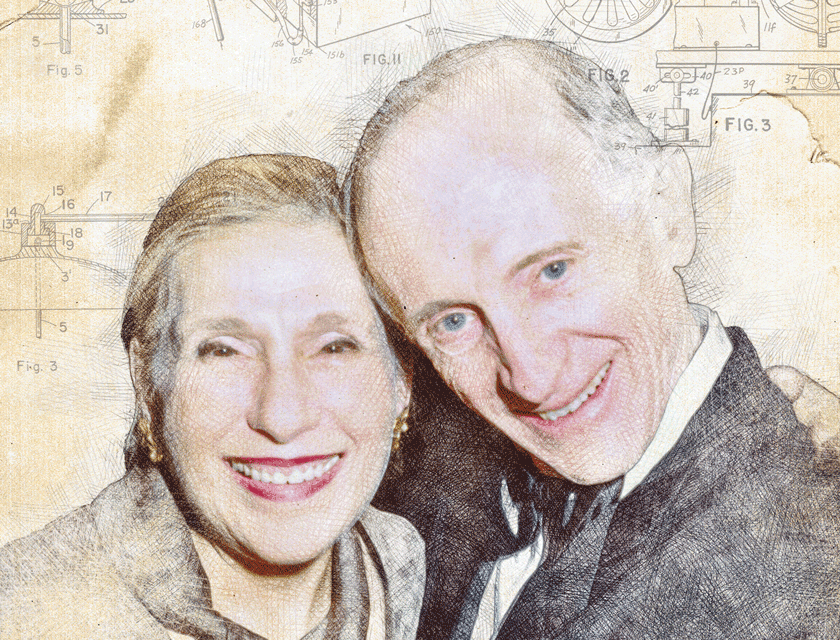

A pneumatic toy airplane was created in 1996 by British inventors

John Dixon and Peter Manning, whose prototype of a compressed air-powered toy airplane was constructed from found parts—primarily a lightweight plastic soda bottle and a hobby air engine.

Canadian toy company Spin Master licensed the technology and hired a renowned toy invention, design and development company in Chicago owned by the Rehkemper brothers.

The company conducted extensive prototyping and engineering efforts using sophisticated CAD engineering software and CNC

machining. They used fresh engine parts and foam fuselages each day after crashing prototypes time and time again until the design was optimized.

“To get the original motor powerful enough and light enough to power the plane sufficiently, approximately 30 motors were machined and assembled, each having minor tweaks as the process of trial and error played out,” Steve Rehkemper said. “At the same time that the motor was being optimized, the foam fuselage was also going through the same optimization.”

During development, test flights were required, which in

turn produced many crashed airplanes for the team. Some of these expensive prototypes were lost in the tops of trees or on the roofs of buildings.

In order to understand whether or not changes made to the motor were really improvements, it was important for the team to be able to exactly duplicate the aerodynamic airframe from scratch—rather than taping or repairing crashed airframes.

Spin Master and the Rehkempers, along with their friend and factory owner in China, William Babbs, built what became the first in a long line of modern-day flying toys. They were branded Air Hogs.

About five years after the first pneumatic planes (Air Hogs) were made and sold, the Rehkempers invented a smaller, lighter and simpler air engine that allowed the plane to become smaller and lighter. This required less air pressure and air volume, thereby requiring far fewer pumps by the user to pressurize.

“This optimized design with a micro air engine is the product we produce and sell today,” Rehkemper said.

That second, more refined version of the Air Hogs airplane is now made and marketed by the Rehkempers through their Top Secret Toys company under the brand name Aero-Storm Pneumatic Airplane.

The Aero-Storm airplane has molded EPP foam wings/fuselage and injection-molded ABS motor/prop subassembly that all attach to a PET air reservoir.

The motor and prop subassembly must be made first and attached to the front of the air reservoir. Then, the foam parts can be added to finish the plane before loading into packaging and making their way to the retail space.